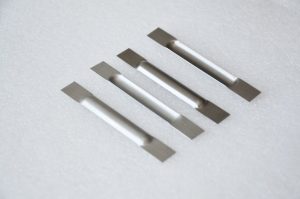

High Purity Tungsten Evaporation Boat

High Purity Tungsten Evaporation Boat Description

High Purity Tungsten Evaporation Boat is a boat-shaped component made of tungsten powder through powder metallurgy process. Wires can be connected at both ends, and low-melting-point metal is placed in the recess in the middle. When electricity is applied, its temperature rises to below 2000 degrees, causing the metal to evaporate. It forms a gas and is plated on the surface of the workpiece above. High Purity Tungsten Evaporation Boat can be divided into stamping boat, folding boat, sintered boat and welding boat, etc. It has high purity, stable resistance, precise size, not easy to deform, good thermal conductivity, excellent high temperature resistance, strong Wear resistance and corrosion resistance. High Purity Tungsten Evaporation Boat is widely used in high-temperature vacuum furnaces or gas-protected furnaces, metal evaporation coating industries, high-temperature sintering industries, ceramic electroplating industries, chemical processing industries and electronic industries (such as picture tubes, household appliances and toys, etc.).

High Purity Tungsten Evaporation Boat Specifications:

|

Material |

W1,W2 |

|

Technique |

Extruding,Forging,Rolling,Machining,Sintering |

|

Purity |

≥99.95% |

|

Thickness |

0.2-0.5mm |

|

Length |

50mm-100mm |

|

Width |

7mm-30mm |

|

Density |

19.2g/cm3 |

|

Melting Point |

3410 °C |

|

Surface |

Bright,Polished,Black,Chemical Clean |

|

Standard |

ASTM, AISI,GB |

|

Certification |

ISO9001;SGS |

High Purity Tungsten Evaporation Boat Picture