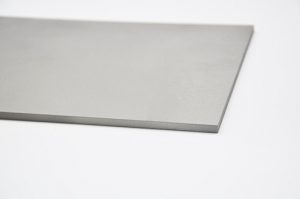

High Temperature Molybdenum Plate

High Temperature Molybdenum Plate Description

We use high-purity molybdenum powder as raw material. Our products have gone through powder pressing, cold pressing or hot pressing molding, high-temperature sintering, cutting and grinding, surface treatment, and final quality control. All products are certified by ISO quality inspection agencies and can be ordered confidently.

Features

- High strength, good toughness, easy processing

- Excellent heat resistance, able to remain stable at extremely high temperatures without softening or melting

- High melting point, low vapor pressure, and good electrical conductivity

- Strong pressure resistance, wear resistance, and long service life

Application

High Temperature Molybdenum Plate广泛应用于各种电极、发热体、溅射靶材、高温舟皿、隔热屏、承烧板、晶体坩埚、射线屏蔽、功率器件散热等场合。

- Electronic vacuum devices can withstand electron beam bombardment in high-temperature environments without deformation or damage. They can also generate high-power radio frequency signals to ensure stable signal transmission and coverage.

- High-temperature furnace field: They are used as heating elements and furnace lining materials in high-temperature furnaces in metallurgy, chemical industry, ceramics and other industries

- Aerospace field: They are often used as engine parts. Their lightweight characteristics help reduce the weight of aerospace equipment and improve its performance and efficiency.

- Scientific research field: They can help researchers manufacture high-temperature experimental devices, conduct material performance tests and chemical reaction research, etc.

High Temperature Molybdenum Plate Specifications:

|

Grade |

Mo1,Mo2 |

|

Technique |

Cold Rolled, Hot Rolled, Welding, Folding, Pressing |

|

Purity |

Mo≥99.95% |

|

Density |

9.8-10.2g/cm3 |

|

Thickness |

4mm-50mm |

|

Width |

10-800mm |

|

Length |

≤1500mm |

|

Surface |

Black Oxide,Polished, Chemically Cleaned, Grinding |

|

Delivery time |

20 days |

|

Standard |

ANSI, ASTM B386, GB |

|

Certification |

ISO9001 |

High Temperature Molybdenum Plate Pictures