Medical Titanium Alloy Wires

Medical Titanium Alloy Wires is one of the refractory metals with many uses in human life. It has unique properties such as high strength, low density, high heat resistance and corrosion resistance. So it is very suitable for application in the manufacturing field, especially in the aerospace industry, but the medical field also often benefits from the application of titanium alloys. There are two commonly used types of Medical Titanium Alloy Wire: Ti-6AL4V and Ti-6AL4VELI, which are mainly made of titanium and processed by voltage, forging, rolling and stretching.

Medical Titanium Alloy Wires has a series of advantages of titanium alloy, such as light weight, low density, low elastic modulus, excellent low temperature bearing performance, non-magnetic, non-toxic, excellent biocompatibility (flexibility and elasticity comparable to than human bone), good corrosion resistance and heat resistance, strong fracture resistance and high cost-effectiveness. Medical Titanium Alloy Wires are suitable for surgical instruments, orthopedics and osseointegration (connection of bone fixation equipment, orthopedic equipment and artificially implanted bone), dental implants, human implants or other auxiliary treatment equipment, etc.

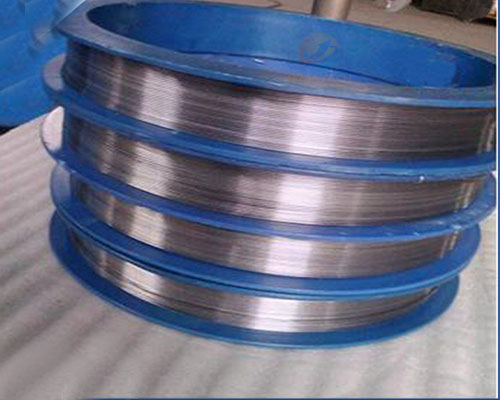

Medical Titanium Alloy Wire Picture:

Medical Titanium Alloy Wire Specifications:

|

|

Al |

V |

Fe |

C |

N |

H |

O |

|

Ti-6AL4V |

5.5-6.75 |

3.5-4.5 |

0.3 |

0.08 |

0.05 |

0.008 |

0.2 |

|

Ti-6AL4VELI |

5.5-6.5 |

3.5-4.5 |

0.25 |

0.08 |

0.03 |

0.012 |

0.13 |

|

Grade |

Ti-6AL4V,Ti-6AL4VELI |

|

Purity |

Ti≥89% |

|

Technique |

Annealed,Hot-rolled,Cold-rolled,Forging |

|

Diameter |

0.08mm-6mm |

|

Length |

500-3000mm |

|

Density |

4.53g/cm3 |

|

Tensile Strength |

≥930 MPa |

|

Surface |

Alkaline Cleaning,Polished,Bright |

|

Shape |

Coil,Straight,Disc |

|

Standard |

ASTM B863,ASTM B348,ASTM F67,ASTM F136,GB,etc. |

|

Certification |

ISO 9001:2015 |