Molybdenum Ion Machined Parts

Molybdenum Ion Machined Parts

Molybdenum Ion Machined Parts Semiconductor ion implantation is a new type of material surface modification technology. It has been widely used in the doping of semiconductor materials, surface modification of metals, ceramics, polymers and other fields. It is a necessary technology for modern manufacturing of large-scale integrated circuits. :

Molybdenum ion machined parts is to inject an ion beam with an energy level of 100keV into a material, and the ion beam has a series of physical and chemical interactions with atoms or molecules in the material. Event ions gradually lose energy and eventually stop, and we are one of the best in the industry for custom and build-to-order ion implanter parts. We will provide your parts with the quality and turnaround time you need. We also manufacture screws, bolts and nuts made of molybdenum, tantalum and tungsten。

|

Property (Unit) |

Purity (%) |

Bulk Density (g/㎤) |

Vickers Hardness (GPa) |

Young’s Modulus (GPa) |

Melting Point (℃) |

Recrystallization Temperature (℃) |

Coefficient of Thermal Expansion (×10-⁶/℃) |

Thermal Conductivity (W/(m・K)) |

Volume Resistivity (Ω・㎝) |

|---|---|---|---|---|---|---|---|---|---|

| Chemical Formula | |||||||||

| Mo | 99.95~ | 10.2 | 1.5 | 327 | 2,623 | 1,000~1,200 |

5.1 (RT) |

142 (20℃) |

5.7 ×10-⁶ |

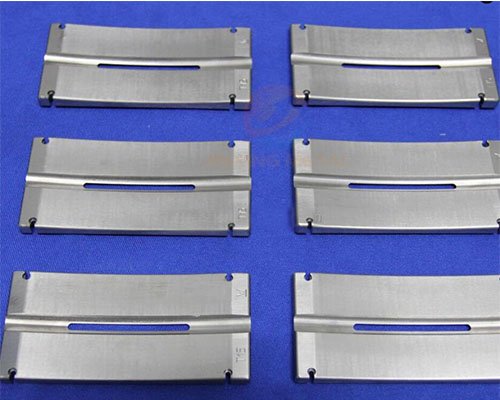

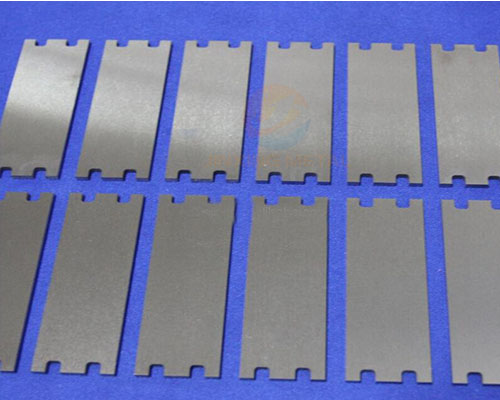

Molybdenum Ion Machined Parts Picture:

Q1: Are you a trading company or a manufacturer?

We are the manufacturer.

Q2: Do you have your own R&D team?

Yes, we can customize products according to your requirements.

Q3: Do you provide samples?

Yes, we can provide samples for free.

The quality of how?

A4: Our experienced engineering team and highly skilled mechanics to ensure the most efficient and highest quality products;

Q4 How do we guarantee the quality?

ISO9001 certificate

Always have a prenatal sample before mass production;

Final inspection before shipment;