Titanium TIG Filler Rod

Titanium TIG Filler Rod Description

TIG welding process, also known as tungsten gas shielded welding, is a non-(non-) MIG gas shielded welding, which uses the arc between the tungsten electrode and the workpiece to melt the metal and form a weld. Titanium TIG Filler Rod is used as a filler metal material in TIG welding process with high tensile strength, good welding performance, high processing efficiency, excellent corrosion resistance, high temperature resistance, strong wear resistance, non-magnetic and excellent biocompatibility. Titanium TIG Filler Rod is made from titanium sponge through a series of processes including melting, rolling, drawing, annealing, and polishing. It can be used in high-temperature welding, heat exchangers, food and chemical industries, biomedics, sports and leisure products, automotive manufacturing, and military industries. If you need cost-effective titanium and titanium alloy products, please send email to contact us.

Titanium TIG Filler Rod Specifications:

|

Grade |

Grade 5 |

|

Material |

Ti-6Al-4V |

|

Technique |

Straightening,Cold Rolled,Hot Rolled,Rolling,Stretching,Annealing |

|

Diameter |

10mm-100mm |

|

Length |

100-6000mm |

|

Tensile Strength |

950MPa |

|

Density |

4.43g/cm3 |

|

Surface |

Polished,bright,Ground,Black Oxide,Pickled,etc. |

|

Standard |

ASTMB863,GB |

|

Certification |

ISO9001 |

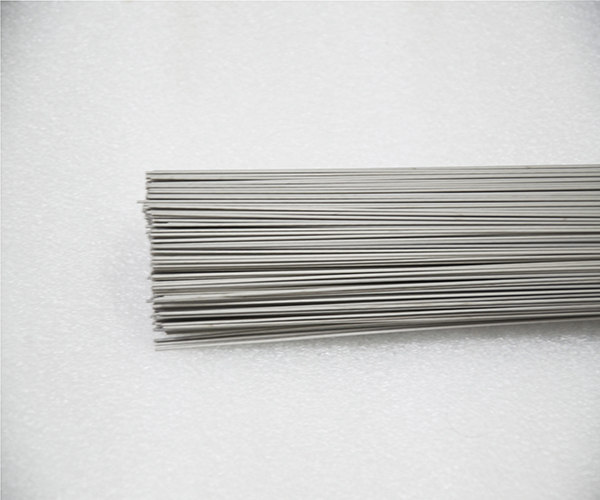

Titanium TIG Filler Rod Pictures: