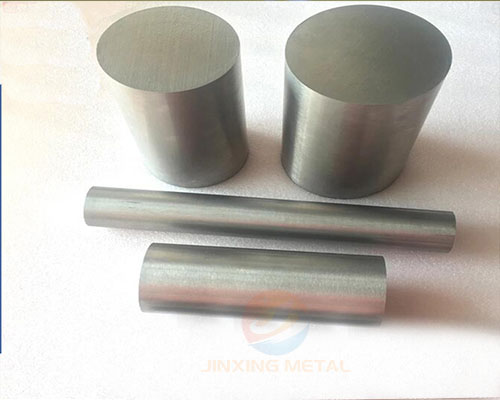

Tungsten Copper Alloy Round Bar W Cu Alloy Bars

Tungsten Copper Alloy Round Bar W Cu Alloy Bars

This Tungsten Copper Alloy Round Bar W Cu Alloy Bars is an alloy composed of tungsten and copper. It is manufactured by powder metallurgy. Tungsten Copper Alloy Round Bar combines the advantages of metal tungsten and copper, it has good electrical conductivity and thermal conductivity, excellent temperature strength and certain plasticity. The manufacturing process includes grinding, mixing of ingredients, pressing, forming, sintering, infiltration and cold working.

Tungsten Copper Alloy Round Bar has the characteristics of uniform organization, high temperature resistance, high strength, arc ablation resistance, high density, and moderate electrical conductivity Using CIP molding, sintering tungsten skeleton, and copper (silver) infiltration process, large-size and special-shaped products of WCu composite material with 6-90% copper content are produced, such as electrical contacts, electrodes, refractory parts, radiators, rocket parts, etc. Small products such as plates are processed by molding, extrusion, and MIM.

W Cu Alloy Bars Properties

| Material | Tungsten Content (wt%) | Copper Content (wt%) |

Density (g/cm³) |

Thermal Conductivity at 25℃ (W/M∙K) | CET at 25℃ (10-6/K) |

|---|---|---|---|---|---|

| W90Cu10 | 90±1 | Balance | 17.0 | 180-190 | 6.5 |

| W85Cu15 | 85±1 | Balance | 16.4 | 190-200 | 7.0 |

| W80Cu20 | 80±1 | Balance | 15.6 | 200-210 | 8.3 |

| W75Cu25 | 75±1 | Balance | 14.9 | 220-230 | 9.0 |

| W50Cu50 | 70±1 | Balance | 12.2 |

W Cu Alloy Bars

Tungsten copper rods are ground, polished, pressed and sintered. All rods are stress relieved and batch controlled. We can provide materials or ISO certification requirements. This tungsten copper rod meets international standards and can be shipped immediately and free of charge. It is very suitable for mechanical workshops, R&D, DIY and laboratories. Tungsten copper has high machinability and is widely used as resistance welding electrodes. Tungsten copper rods also have excellent electrical conductivity. Volume discounts are feasible. Please contact us for details