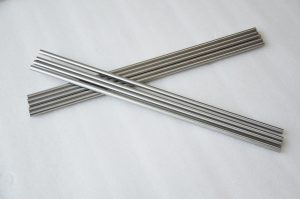

TZM Molybdenum Rods And Bars

TZM Molybdenum Rods And Bars Description

TZM alloy (Titanium-zirconium-molybdenum) is a molybdenum based superalloy containing 0.50% titanium, 0.08% zirconium and 0.02% carbon. There are two main preparation methods: powder metallurgy and arc melting casting. TZM Molybdenum Rods And Bars have been applied to large mechanical loads with excellent physical and chemical properties, such as high melting point, high elastic modulus, low linear expansion coefficient, low vapor pressure, high strength, excellent high temperature resistance, corrosion resistance, good electrical and thermal conductivity, wear resistance and low processing cost. TZM Molybdenum Rods And Bars are often processed into heating electrodes in the glass industry, lamp holders for electric light sources, engine components in aerospace engineering, stirring rods, vacuum furnace screws, high-temperature structural components and other materials in the rare earth smelting industry.

TZM Molybdenum Rods And Bars Specifications:

|

Main Components |

Ti:0.4-0.55%,Zr:0.06-0.12%,C:0.01-0.04% |

|

Purity |

≥99.95%-99.99% |

|

Diameter |

10-200mm |

|

Length |

<2000mm |

|

Hardness |

240-280HRA |

|

Density |

9.8-10.2g/cm3 |

|

Surface |

Polishing,Grounding |

|

Delivery Time |

20 days |

|

Standard |

ASTM B387,GB |

|

Certification |

ISO9001 |

TZM Molybdenum Rods And Bars Picture