Wolfram Copper Alloy Bars For Welding

Wolfram Copper Alloy Bars For Welding

Wolfram Copper Alloy Bars For Welding is a composite material of tungsten and copper, which has the excellent properties of tungsten and copper, such as heat resistance, low thermal expansion, high arc resistance, good electrical conductivity, high heat, ablation resistance, high strength, excellent thermal conductivity and conductivity. Tungsten copper alloy is easy to process. Because of its high hardness, high melting point, and anti-adhesion characteristics, tungsten is usually used for projection welding and butt welding electrodes with certain wear resistance and high temperature resistance.

Using CIP forming, sintering tungsten skeleton and copper (silver) infiltration process, produce large-sized and special-shaped tungsten-copper composite products with copper content of 6-90%, such as electrical contacts, electrodes, refractory parts, radiators, Rocket parts, etc., can also produce small products such as tungsten-copper alloy sheets, pipes, and plates through molding, extrusion, and MIM processes.

Wolfram Copper Alloy Bars For Welding application:

1) Arc contacts and vacuum contacts in high and medium voltage circuit breakers or vacuum interrupters

2) Electrodes for resistance welding;

3) Radiators as passive cooling elements for electronic equipment

4) Electrode in EDM cutting machine

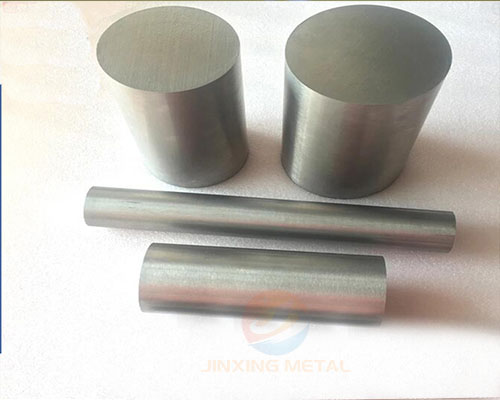

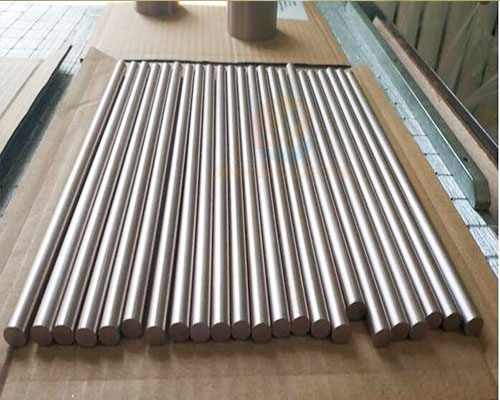

Wolfram Copper Alloy Bars For Welding Picture:

Chemical Composition of Wolfram Copper Alloy Bars For Welding

|

Class |

Chemical Composition(Wt%) |

Density |

Hardness |

Resistance rate |

IACS |

Bending strength |

||

|

Cu |

Total Additives≤ |

W |

g/cm3≥ |

kgf/mm4≥ |

um.cm≤ |

%≥ |

MPa≥ |

|

|

W93Cu07 |

7±1.0 |

0.5 |

balance |

17.5 |

270 |

7.2 |

26 |

1190 |

|

W90Cu10 |

10±2.0 |

0.5 |

balance |

16.75 |

260 |

6.5 |

27 |

1160 |

|

W85Cu15 |

15±2.0 |

0.5 |

balance |

15.90 |

240 |

5.7 |

30 |

1080 |

|

W80Cu20 |

20±2.0 |

0.5 |

balance |

15.15 |

220 |

5.0 |

34 |

980 |

|

W75Cu25 |

25±2.0 |

0.5 |

balance |

14.50 |

195 |

4.5 |

38 |

885 |

|

W70Cu30 |

30±2.0 |

0.5 |

balance |

13.80 |

175 |

4.1 |

42 |

790 |

|

W65Cu45 |

45±2.0 |

0.5 |

balance |

13.30 |

155 |

3.9 |

44 |

650 |

|

W60Cu40 |

40±2.0 |

0.5 |

balance |

12.75 |

140 |

3.7 |

47 |

600 |

|

W55Cu45 |

45±2.0 |

0.5 |

balance |

12.30 |

125 |

3.5 |

49 |

565 |

|

W50Cu50 |

50±2.0 |

0.5 |

balance |

11.85 |

115 |

3.2 |

54 |

534 |